A great product is born out of every detail

Frigorífico Las Piedras S.A. is a family-owned meatpacking business that started in 1978. Two years after its grand opening, it carried out its first shipment for export.

The only entirely nationally funded meatpacking plant of its stature, Las Piedras has become one of the top meatpackers in the industry.

Conveniently located 20 minutes from the Port of Montevideo, Las Piedras' 24,000-square-meter plant is built on a 110-hectare property. Production is carried out in harmony with its surrounding natural environment, seamlessly combining technology and good practices to achieve it.

The animals processed in our plant come from a known source, thanks to the loyalty program carried out between Las Piedras producers. The plant boasts an avant-garde electronic traceability system to track all livestock.

Las Piedras is the largest steer packer in Uruguay; featuring the latest technology for boning, a large-capacity cold storage chamber for maturation, and all the equipment necessary to guarantee meat quality.

Together with our loyalty plans, including San Alberto Angus, our production process complies with strict sustainability and animal wellfare standards.

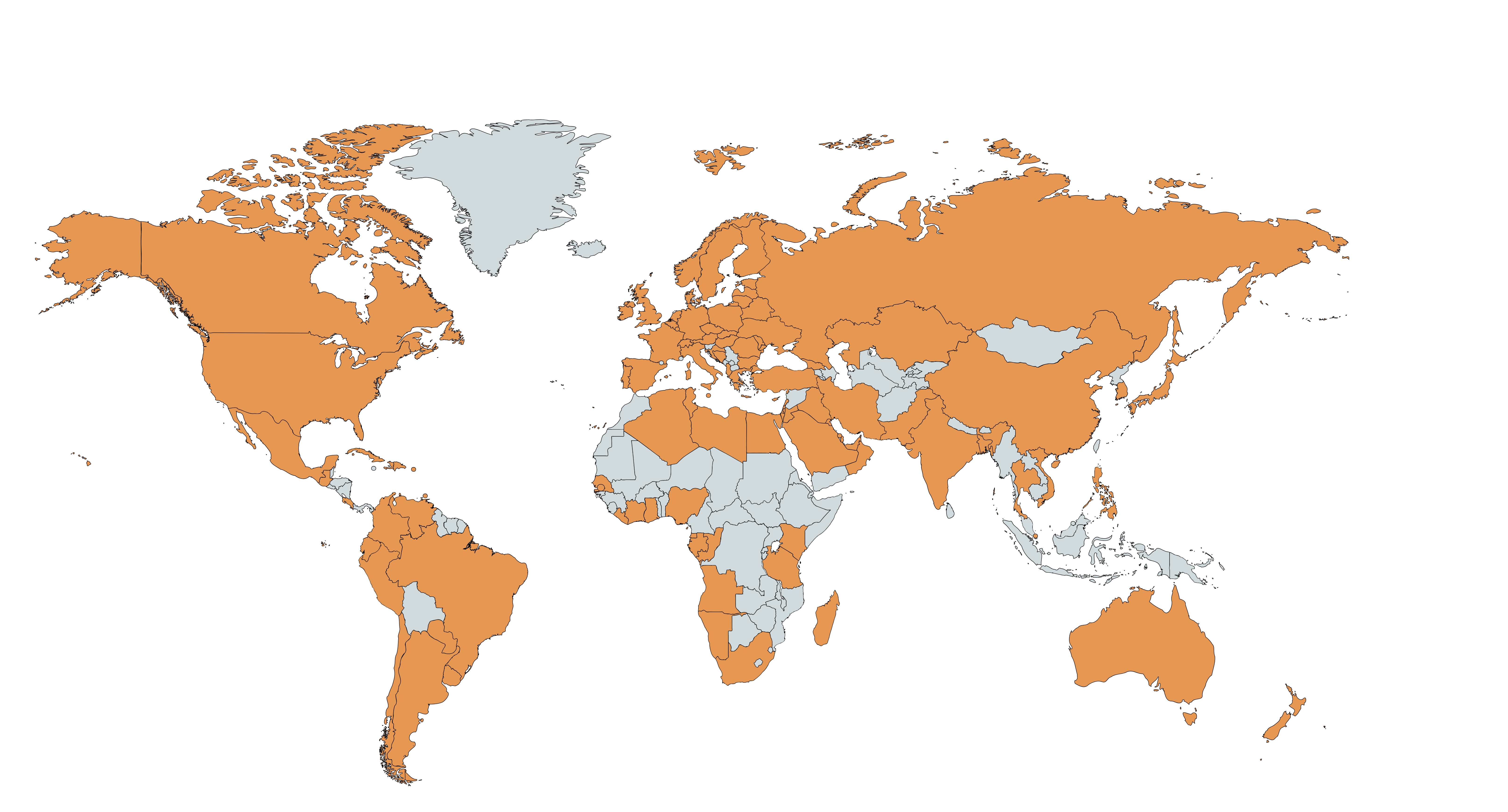

Our meat is served in top restaurants over the world. Through the most outstanding chefs, we have been providing quality and excellence for over 30 years.